SUREPRINT Doctor Blades

are manufactured from highly refined strip

steel specially selected for Doctor Blades.

The final finished product is finished with

a extra-smooth edge ensuring that the blades

perform a clean wiping action on the gravure

cylinder/anilox roller immediately on start-up.

"Every metre

of Doctor Blade is physically inspected to ensure

that the customer receives a totally defect

free product every time thereby eliminating

expensive press downtime."

SUREPRINT Doctor blades

can be used for Rotogravure and Flexographic

printing as well as for coating applications.

These doctor blades are available in several

varieties and edge configurations based on

customer application and process requirements. These

are enumerated below:

HIGH CARBON STEEL BLADES

-

SUREPRINT-STANDARD: High

density carbon steel blades having a refined

microstructure suitable for Standard Rotogravure

& Flexographic printing and coating

applications with solvent and water based

inks.

-

SUREPRINT-PLUS: High

density carbon steel doctor blades having

an Ultra-refined microstrucuture which allows

for low friction doctoring with minimum

wear ensuring LONG RUNNING LIFE. This blades

is useful for long run jobs and/or when

working with abrasive inks to ensure efficient

printing press performance with minimum

downtime.

-

SUREPRINT- ULTRA PLUS : Premium High Quality doctor blade manufactured from a specially formulated steel suitable for low pressure doctoring at high line speeds with even longer running life. Suitable for both Gravure and Flexo printing.

-

SUREPRINT-EXCEL

:

Top of the line High performance doctor

blade offering long running life with

excellent properties to eliminate streaks and

drag outs. Suitable for high quality

Rotogravure and Flexographic printing.

:

Top of the line High performance doctor

blade offering long running life with

excellent properties to eliminate streaks and

drag outs. Suitable for high quality

Rotogravure and Flexographic printing.

STAINLESS STEEL BLADES

SUREPRINT-STAINLESS: Ultra-refined

High quality doctor blades for high corrosion

resistance and long running life.Useful when

printing with water based inks with high PH

value.

BLADE EDGE CONFIGURATIONS:

SUREPRINT Doctor Blades are

available in several edge configurations:

1. LAMELLA EGDE :

also commonly called STEP Edge is the most

commonly used edge configuration preferred

by customers.

Incorporating the latest technology, SUREPRINT

Doctor blades increase productivity, improve

quality and reduce wastage or rejections.

The unique shape of the lamella ensures that

a constant contact area with the cylinder

is maintained throughout the life of the blade.

Resulting in uniform printing throughout the

print run. Thus no resharpening is required.

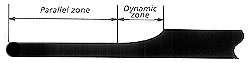

The novel shaping process of the lamella

ensures that there are no longitudinal grinding

scratches or shed marks.Also, The parallel

zone of the lamella ends in a smooth taper

called dynamic zone which reduces vibrations

and fatigue.

The Sureprint advantage

- over conventional blades:

-

The blade life is atleast upto 6

times longer than a conventional blade.

-

The contact area remains constant

throughout the entire life of the

doctor blade.

-

No change in the tonal values through

blade wear.

-

Minimal doctor blade pressure reduces

chrome destruction and extends

cylinder life.

-

Less wastage and rejections.

-

No running-in time required.

-

No doctor blade grinding equipment

required.

-

Less downtime caused through replacement

of doctor blades

-

Constant conditions for proofing(no

tonal variations and easy colour matching.

|

|

2.

STRONG LAMELLA: This is basically

a lamella type blade where instead of the

edge being absolutely parallel to the main

blade body it is tapered between 5 to 30 microns

depending on customer requirements.This doctor

blade edge helps to minimize print errors

with poor doctor blade settings and to make

it a little more"forgiving". The

blade has a gradual contact edge and has increased

strength to better support the lamella.

2.

STRONG LAMELLA: This is basically

a lamella type blade where instead of the

edge being absolutely parallel to the main

blade body it is tapered between 5 to 30 microns

depending on customer requirements.This doctor

blade edge helps to minimize print errors

with poor doctor blade settings and to make

it a little more"forgiving". The

blade has a gradual contact edge and has increased

strength to better support the lamella.

3. Other edge configurations, such

as Round Edge blades are

also available on request.

More

>>